Fluidized Thermal Backfill FTB is used to encase and cover underground power conduits that will contain transmission or distribution cables which may operate at or above normal ampere capacity ampacity. Such backfills include thermal concrete fluidized thermal backfill controlled density fills that have low thermal resistivity.

At the time of installationmeans that Portland cement and water are added and mixed less than 10 minutes before pouring and preferably seconds before pouring or as a mix is poured.

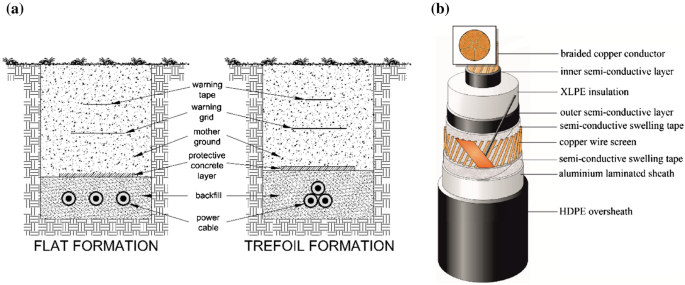

. Fluidized Thermal Backfill Standard Number. Fluidized Thermal Backfill a trademark of Geotherm Inc is a form of controlled low-strength material composed of certain types of stone sand fluidizing agents and cement specifically designed to dissipate the heat generated by underground electric transmission cables within city streets or on rural wind farms. Thermal Backfill for Underground Power Cable Installations August 11 2014 C-UG-2050 Transmission Distribution Standards Page 1 of 4 Application Flowable Thermal Backfill FTB is placed around power cable conduit runs to more effectively dissipate heat generated by the cables into the surrounding environment.

MIX DESIGN The task of developing a fluidized thermal backfill proceeded from a clear under standing of the thermal behaviour of a three phase material such as soil. FTB Fluidized Thermal Backfill proper cable laying methods fibre concrete cable protection tiles trench backfill materials. The thermal conductivity of the composite media depends on the thermal conductivity of the individual components their proportion and nature of dispersion.

20 APPLICABLE DOCUMENTS R20 APPLICABLE DOCUMENTS 21 ASTM Standards C 403 The intent of the guide is to use the most current Time of Setting of Concrete. 715000 September 8 2021 October 8 2021 3 of 4 42 Mix Design Criteria FTB mix designs shall meet or exceed the performance requirements cited in Table 4. This also will include a thermal dryout curve.

Our products will create a stable thermal environment for the expensive high voltage cables assisting them to operate efficiently at safe temperatures and for the life expectancy anticipated. Choose the design thermal rho values for the native soil and thermal backfill. A weil formulated Fluidized Thermal Backfill FTB is a cast effective means 01 providing the optimum thermal resistivity and thermal stability characteristics.

FTB transfers heat away from power cables allowing them to conduct more power. Afterwards concretes with extremely high thermal conductivities were developed 2. Choose the design thermal rho values for the native soil and thermal backfill.

Source and design the fluidized thermal backfill or compacted granular backfill based on locally available materials. One of the best performing backfills was a Fluidized Thermal Backfill FTB containing sand aggregate cement and fly ash. The flowable thermal backfill has a low thermal resistivity useful for filling trenches containing electrical cables and other lines that generate heat.

The best backfill available in Brazil today is composed of materials from volcanic rocks that provide thermal resistivity of 1 Km W for driedmaterial. This also will include a thermal dryout curve. The FTB is an engineered material that has very low thermal resistivity even when totally dry and has very long thermal dryout times thermally very stable.

This also will include a thermal dryout curve. Cables with a smaller cross-sectional area may be used when thermal backfills with higher conductivity are applied which results in the decrease of the material costs cable and backfill cost of the system 4. InTerras Thermal Product Lines of Fluidized Thermal Backfill FTB Thermal Concrete and Thermal Grout are the solution to your heat transfer requirements.

Thermally stable fluidized backfill began in the eighties 1. Recommended that the mix design be given to a. Geotherm was founded in 1978 by Deepak Parmar in the Greater Toronto area of Canada.

However this backfill is quite strong and thus would be difficult to excavate. 43 Air Content The total air content of any FTB mix shall not exceed 2 by volume. FTB can be made trom locally available aggregates and is installed as a con trolled density Ilowable fill using ready-mtx concrete trucks.

Corrective thermal backfill significant cable ampacity. Achieving soil density is needed in the restricted trench areas near cables or around cable pipe groups where proper compaction is difficult. Unit weight of unhardened CLSM is not needed for verification of non air - entrained C LSM mixtures.

The invention includes a method of making and using a flowable thermal backfill. An alternative is the Fluidized Thermal Backfill FTB with thermal conductivity of 154 Wm K in the dry state and a higher cost about 125 EURm 3. Choose the design thermal rho values for the native soil and thermal.

Source and design the fluidized thermal backfill or compacted granular backfill based on locally available materials. The method includes process steps of blending ingredients of stone sand and fly ash making a flowable thermal fill by mixing the blended. While at Ontario Hydro Research Deepak worked on a research project sponsored by EPRI to help design a fully automated and portable test instrument for the measurement of thermal properties of native soils rock high strength.

A typical mix design consists of 15 parts sand to 1 part cement mixed with about 10 parts water. Recordation to the theoretical mix design submitted and approved by the engineer. Backfill o SVP Public Works Contract 2114B Project Specifications 2012 Section 3310 Fluidized Thermal Backfill o Transmission Distribution World April 1 2003 Underground Cables Need a Proper Burial Deepak Parmar and Jan Steinmanis Rescissions.

Source and design the fluidized thermal backfill or compacted granular backfill based on locally available materials. Fluidized Thermal Backfill 15 miles Summer 2015 Tom Murphy CMElectrical Inspector National Grid 339-221-3616 Carusso McGovern master contract Eastern MA National Grid Flowable Fill --- November 2012 - Current Riley Brothers master contract Eastern MA National Grid Flowable Fill --- August 2011 - December 2012 Feeney Brothers master. The method includes process steps of blending ingredients of stone sand and fly ash making a flowable thermal fill by mixing the blended stone sand and.

Analysis Of An Application Possibility Of Geopolymer Materials As Thermal Backfill For Underground Power Cable System Springerlink

Thermal Products Interra Innovation

Fluidized Thermal Backfill Geotherm Usa

Fluidized Thermal Backfill Geotherm Usa

Fluidized Thermal Backfill Geotherm Usa

Collection Circuits J Mc Calley Highlevel Design Steps

0 komentar

Posting Komentar